RFID (Radio-Frequency Identification) tags for Wood Identification

The barcode consists of a machine-readable code in the form of numbers and a pattern of parallel lines of varying widths, which is printed on an item or product.

This is a high reliability and accuracy method (Mousavi et.al. 2005). The RFID tag is extremely small and can be affixed to an object and used to track and manage inventory, assets, wood, etc. (Várallyai, 2013). Radio Frequency Identity (RFID) tags can be planted inside a wood log and transmit data to receivers. These RFID tags can be read-only or read-write, and can be programmed in the field or in advance. They are passive; they only transmit data when become ‘excited’ by a signal from the RFID reader. These tags are very durable, they can live up to 8 years, they can be reprogrammed and they can be read under water. Aiming to automatic identification and tracking, radio-frequency identification (RFID) uses a wireless non-contact system with radio-frequency electromagnetic fields for data transmission from a tag, in a product (Mousavi et.al. 2005). There is comprehensively literature about RFID technology reviewed in recent research (Várallyai, 2013), where it is studied the use of RFID aiming to improve supply chain and inventory operations. RFIDs are simple to hide or fit in other items due to its small size. The RFID technology is the most promising method for marking logs at this moment, as, unlike barcodes technology, RFID allows acquiring information at a rate of 1000 tags per second and it is expected a growing acceptance of RFID technologies in the next years as basic components within traceability information systems (Bechini et.al., 2008). The readability in the real-life tests and demonstrations was close to 100%. Apart from the technical performance RFID represents a sophisticated technology that opens up for new business applications. A further advantage compared to other methods is that it is not easy to deceive (Dykstra et.al. 2003). Still there is a need for further development of this technology. The automatic application must be very tough with a minimum of production disturbances. The current trend is positive for the RFID technology and generally the cost per tag is expected to decrease (FSANZ, 2012). Traceability in wood packaging material can be secured with the suitable thermal handling, as the technology of radio gives today adequate solutions. Apart from the simple thermal handling in wooden packaging material, other information can be stored on the same label such as quantity and origin of wood (Ntalos et.al. 2010). The cost of the method is now high but it still decreases.

Technological limitation of RFID Tags:

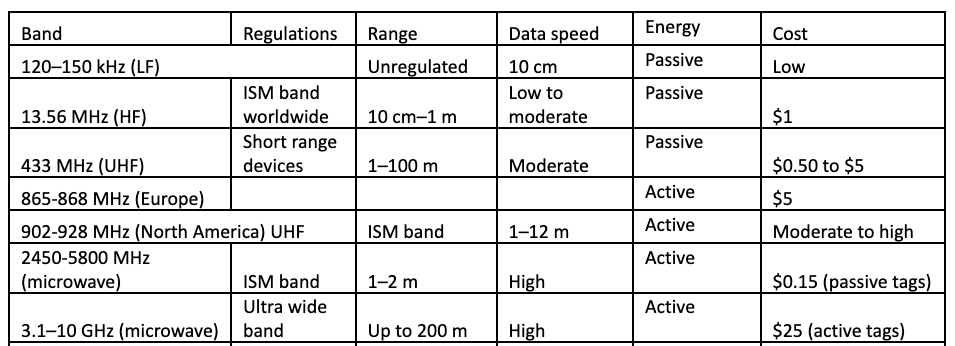

Generally speaking RFID tag maximum read distances are as follows:

- 125 kHz. and 134.3 kHz. Low Frequency (LF) Passive RFID Tags -read distance of 30 cm or less - usually 10 cm (4 inches) unless you are using a very large tag which can have a read distance of up to 2 meters when attached to metal.

- 13.56 MHz. High Frequency (HF) Passive RFID Tags - maximum read distance of 1.5 meters - usually under 1 meter.

- 860 ~ 960 MHz. Ultra High Frequency (UHF) Passive RFID Tags - minimum read distance of over 1 meter. Gen2 tags can have a read range of up to 12 meters. However new generation of IC's plus antenna designs are now pushing this distance to over 15 meters!

- Gen 2 Semi-active battery assisted tags are semi-passive (semi-active) tags have a read range of up to 50 meters. Gen 2 Semi-active tags are just emerging on the market.

- 860 ~ 960 MHz. 3rd and 4th Generation IC/Silicon - The new generation 3 and 4 are now available in numerous inlay designs. This new silicon (IC) provides up to 40% more sensitivity while reducing RF interference. This means that a tag using this new generation of silicon can have a read range of over 16 meters under FCC regulations of 4 watts EIRP.

- RTLS - Real Time Location Systems - Usually LF and SHF - now you can have a UHF RTLS that is extremely accurate and can easily control 23,000 Square Meters on a single switch.

- 433 MHz Ultra High Frequency Active (require a power source) RFID Tags - up to 500 meter read range SkyRFID carries a complete line of 433 MHz readers and tags that can be used for many industrial, healthcare, mining, and other tracking and locating applications.

- 2.45 GHz. Super High Frequency Active (require a power source) RFID Tags - up to 100 meter read range. There are several different modulations for 2.45 GHz. and you can also have real time location information from these active tags.

LLanthu

Traceability and transparency platform for the agricultural industry using blockchain technology (IPFS, Ethereum and Solana).

Our platform provides transparency and traceability in the agricultural supply chain, from the producer to the final customer, and... allows the end customer to recognize the work of the producer...